In building materials (and not only) adhesion and adherence are the result of two different mechanisms that can be present both separately and, as more often happens, in coaction: mechanical adhesion and chemical adhesion . The osmotic or diffusive adhesion also comes into play in the osmotic process.

MECHANICAL ADHESION

Mechanical adhesion depends, to a large extent, on the degree of preparation of the substrates, in particular on their degree of cleaning and roughening as well as on their saturation.

CHEMICAL ADHESION

Chemical adhesion, pertaining to molecular interactions, depends on the nature of the adhesive, on its compatibility with the support and, in turn, on the degree of preparation of the surfaces.

OSMOTIC OR DIFFUSIVE ADHESION

In osmotic systems there is also a specific adhesion, which is realized through the two coagent processes, of diffusion and crystalline deposition, often defined osmotic or diffusive, dependent on the “osmotic capacity” of the material and, once again, from the level of preparation of the surfaces.

From the functional framework emerges as a relevant factor, the significant contribution represented by the osmotic adhesion, without prejudice to the importance of the effective “osmotic capacity” of the material used and of the correct preparation of the supports which, if lacking, can however compromise the effectiveness of the intervention.

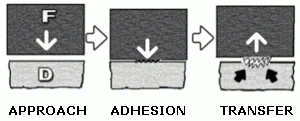

The compatibility between the materials participating in the adhesive process is fundamental in order to avoid detachments by transfer from a stronger material (F) to a weaker material (D).

The osmotic cementitious compounds are produced in two different formulations: mono-component (rigid) and bicomponent (deformable).

In the one-component osmotic cementitious systems osmotic, diffusive and mechanical adhesion is prevalent, while in bi-component osmotic cement systems , the chemical, mechanical and diffusive adhesion is prevalent.

The choice of a type of two-component coating rather than one-component and with more or less high deformability characteristics, is influenced by the knowledge of the morphology of the work to be coated, its predictable structural behavior, as well as the characteristics of the support.

Compared to single-component systems, the adhesion of chemical / mechanical / diffusive type combined with a better capacity of deformation, provided by bicomponent systems, assumes particular relevance in the presence of thin structures and / or subject to elastic movements.

In the presence of massive, stable (rigid) structures, with adequately prepared supports, the mono-component osmotic may be the most suitable product.