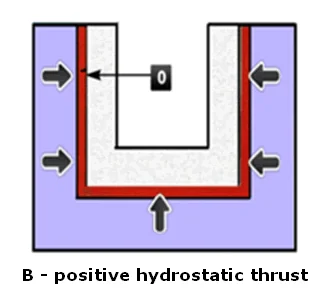

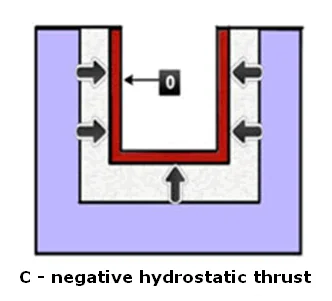

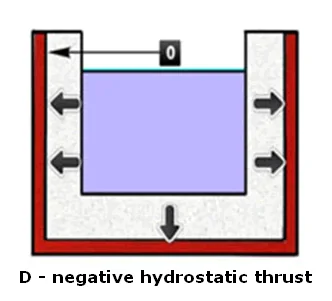

The usual uses of osmotic cement coatings, contemplate situations in which the liquid must be prevented from “going out” (figures A and D) and applications in which the liquid must be prevented from “getting in” (figures B and C).

The result is operating conditions subjected to positive hydrostatic thrust (thrust) and negative hydrostatic thrust (counter thrust) .

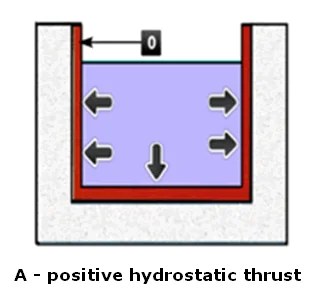

In the following images:

The condition of positive hydrostatic thrust (upthrust), occurs when the liquid exerts pressure directly on the coating, which is then compressed on the support: images A and B;

The condition of negative hydrostatic thrust (counter-thrust), occurs when the liquid exerts pressure at the coating adhesion interface exerting pressure aimed at detaching the coating from the support: images C and D.

NB : In the images the osmotic coating is indicated with the letter (O).

While in the presence of positive hydrostatic thrusts (1) the most important characteristic is intrinsic impermeability, in the presence of negative hydrostatic thrusts (2) , as in the case of structural movements, it is the adhesion to the support that assumes fundamental value.

To fully achieve the performance of osmotic cementitious waterproofing, especially in counterthrust, the porosity of the support (which in concrete is equal to approximately 200,000,000 / m²), is a resource that must be “opened” to osmotic diffusion!